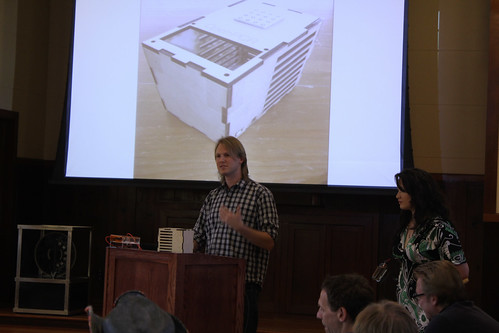

One of our main goals for the OpenPCR project is to enable people to do PCR. With our first prototype we’re getting tools into the hands of people — with off the shelf parts, flexible design, and free control software.

What about enabling people to do PCR after they have the tool? What about helping them actually run their first reaction (does anyone get it right the first time?), their second reaction, or their 50th sample. How do we enable that?

I’ve broken “Make PCR easy” into 3 chunks:

1. Make mistakes!

2. Share mistakes!

3. Learn from mistakes!

Software

Sharing: twitter, facebook, human readable protocols

Troubleshooting: “Help!!” – heres a “troubleshooting” process for both newbies and veterans: https://www.bio.uio.no/bot/ascomycetes/PCR.troubleshooting.html

Other stuff

Since it’s a given that your first few reactions on a new machine won’t work, is there a standard curriculum used to train newbies? A sampler that opens your eyes to several PCR techniques?

Or a “is my PCR machine working correctly” wet/dry test? We are proposing that people build their own PCR machines, which hasn’t been done before.